AIRCRAFT OpenFOAM SIMULATION (BOEING 747)

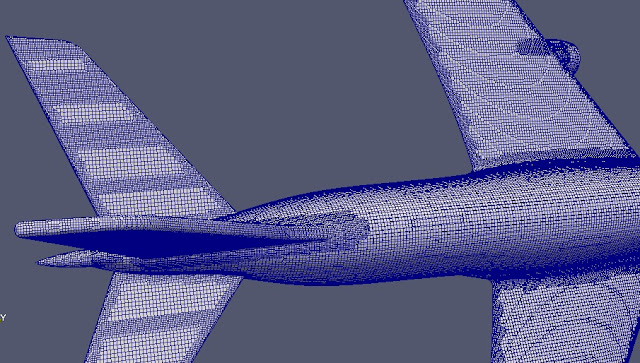

Before I begin to furnish the results, a quick look at the computational resources that were utilized for the simulation. I possess a minimal capability laptop manufactured by Hewlett-Packard, which runs on 2 core(s) and a 4 GB RAM. The objective of the simulation is to set up a 3D mesh for an Aircraft flow simulation with a resolved boundary layer of Y+ < 1, and to study the Residuals . The kOmegaSST turbulence model was adopted. The STL file downloaded online is a scaled Boeing 747 model, with the elevator tabs deflected downwards. Figure No.1: Rear View The cell size in the blockMesh is 0.05, owing to the fact that a scaled 747 model was selected, otherwise a cell size of 0.5 can be executed for an un-scaled model. Regardless, any of the following cell size can be applied (0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0). Four boundary layers were generated with an expansion ratio of 1.2, adding to the total cell count of over 3 million cells. A steady-state solver